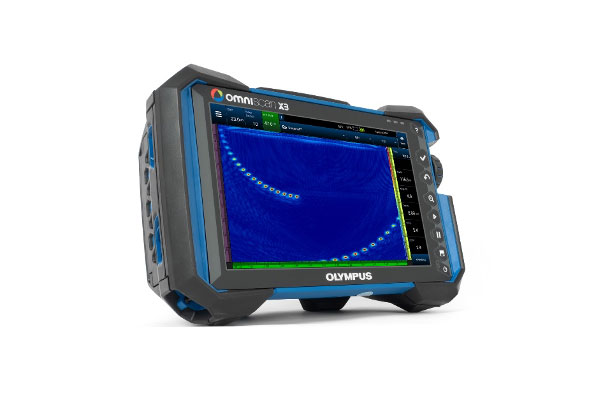

When launching the multi-element ultrasonic flaw detection unit OmniScan™ X3 By the end of 2019, Olympus had designed it to be a powerful yet easy-to-use multi-element ultrasonic inspection tool (PAUT). As it is highly versatile and even supports the total focusing method (TFM), inspectors who use it enjoy all the confidence they need to make decisions.

Members of the Italian Welding Institute (Istituto Italiano della Saldatura, IIS) are regulars on Olympus NDT equipment, and were among the first to use the OmniScan X3 flaw detector. IIS is made up of a non-profit association and three limited liability companies, which provide certification (IIS CERT), training (IIS PROGRESS) and services (IIS SERVICE) to engineers in Italy and abroad.

Simone Rusca, in charge of training, controls and inspections at the IIS, is responsible for organizing the training courses. He explains: "The IIS gave its first training course in 1951. At present, we train around 1,000 people a year: welding engineers, welding inspectors, NDT operators at levels 1 to 3, and so on. Our trainees come from a wide range of sectors, mainly the oil and gas industry, but also construction, railroads, automotive, marine, aeronautics and aerospace.

"We provide training in a range of NDT methods, such as those described in ISO 9712 (qualification and certification of NDT personnel). These methods include dye penetrant testing, magnetic particle inspection, radiographic inspection and, of course, ultrasonic inspection, both with conventional techniques and with advanced inspection techniques such as multi-element or time-of-flight diffraction (TOFD) technology".

The importance of state-of-the-art training equipment

IIS has been using Olympus equipment for some 20 years. As Simone Rusca explains: "We always want to use state-of-the-art equipment in our training courses, because our participants benefit greatly from it. This state-of-the-art equipment includes, of course, the OmniScan X3, but also new components, probes and software manufactured by Olympus".

"Our NDT specialists are very happy and satisfied with the new equipment. We currently use the OmniScanX3 with two different probes: 32-element linear array and 64-element linear array. We use both multi-element ultrasonic and FMC (full matrix capture); in general, it's this equipment that we use to demonstrate to our participants the sensitivity of these new techniques and the ease of use of the device. Feedback from participants and our trainers has been very positive; the equipment is proving to be an excellent tool for improving their skills".

Simone Rusca adds: "Another key advantage for us is the great versatility of the OmniScan X3, which can be adapted to a variety of inspection applications. Our course participants typically inspect many different components for various indications and defects, and the OmniScan X3 lends itself perfectly to this need for adaptability."

Teaching the TFM method

The OmniScan X3 flaw detector fully supports the all-point focusing method (total focusing methodTFM). Component inspection using the TFM method provides greater clarity and resolution, ensuring better detection of small defects, such as those caused by early high-temperature hydrogen attack (HTHA). The OmniScan X3 flaw finder can display four TFM modes simultaneously, facilitating flaw interpretation and sizing.

OmniScan X3 fault-finding device with TFM function

Commenting on the TFM method, Mr Rusca says: "We're integrating it into our training, and the technicians are very happy and satisfied that it's now available on the OmniScan X3. However, the main challenge with new techniques, such as TFM, is that they are not yet fully standardized, so it's often difficult to give a precise answer, as we can't compare TFM results with those of a reference procedure. Nevertheless, in absolute terms, the sensitivity is very good.

A strong collaborative relationship

The close collaboration between Olympus and IIS is mutually beneficial. The IIS has a large number of highly qualified NDT inspectors with a wealth of theoretical and practical knowledge. Their contribution and understanding of NDT and equipment helps Olympus to better understand the needs of its customers.

Mr. Rusca adds: "I think this collaboration is a good reflection of setting standards of excellence in training and equipment. We are always on the lookout for new technologies, new solutions and advice to improve NDT methods, and we very much appreciate Olympus' contribution in this respect".

Media kit

Media kit