Can you ensure end-to-end quality control for your finished products? For critical applications, it's important to maintain high quality standards at every stage of your supply chain, from incoming goods through the manufacturing process to final assembly. To help you improve your quality control and assurance process, hand-held analyzers with X-ray fluorescence (XRF) technology are excellent tools.

This blog post describes the benefits of handheld XRF analyzers used for quality control and quality assurance, as well as providing practical tips for achieving end-to-end quality control in the manufacturing industry.

Advantages of using hand-held XRF analyzers for quality control and assurance in the manufacturing industry

Visit X-ray fluorescence technology is a technique for verifying the composition of metals. It provides precise elemental analysis and grade identification. You can use it to analyze a variety of metal materials, including sheets, rods, tubes, bars, wires, powder and finished products, making it a practical method for materials verification. Other advantages of this method include:

- Minimum sample preparation : In most cases, alloy analysis requires little or no sample preparation.

- Non-destructive analysis method : Hand-held XRF analyzers leave no marks on the metal alloys analyzed.

- Ease of use : Simply position the analyzer and pull the trigger to quickly obtain analysis results for common alloy grades.

- Quick analysis: One or two seconds is all it takes to achieve immediate results for common alloy grades.

- Portability : Lightweight and portable, hand-held XRF analyzers can be easily transported and used anywhere in your facility.

Now that you're more familiar with the benefits of hand-held XRF analyzers for quality control, quality assurance and material verification, we'd like to offer a few useful tips to help you get the most out of your instrument.

Nine ways to use your handheld XRF analyzer for end-to-end quality control in the manufacturing industry

Here are a few ways to use your Vanta™ XRF analyzer to ensure quality control throughout your manufacturing process:

1. Check materials at any time of day, anywhere in your facility.

Vanta's hand-held XRF analyzers meet the requirements of certain IP protection ratings and have been tested for drop resistance, ensuring greater durability and uptime in manufacturing environments and enabling your team to make rapid decisions on material quality in addition to maintaining a good level of productivity all day long.

2. Reduce operator training time with user-friendly software.

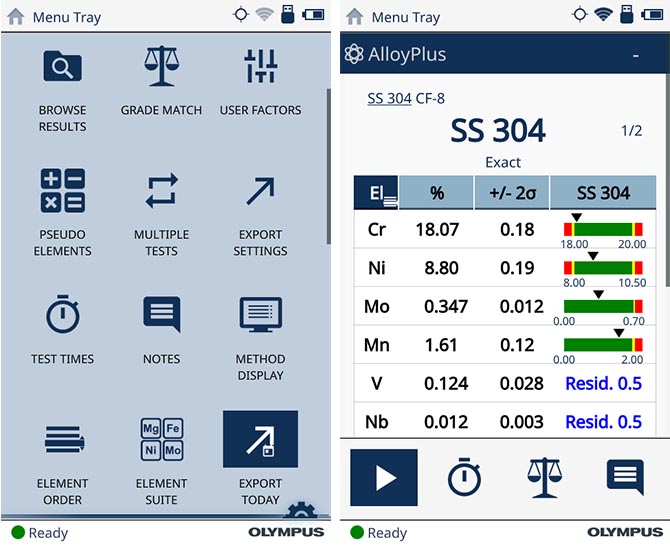

The Vanta analyzer's user-friendly interface is easy to operate, thanks to its multi-function mobile phone-like operation. Customizable operator instructions and clear "pass/reject" results make it easy to learn and use, reducing the risk of human error.

.

The Vanta analyzer's user interface is similar to that of a multifunction cell phone, reducing operator training time and improving productivity.

3. Customize the shade library to suit your application.

Shade matching is easy with 600 unique shades in the customizable shade library. The trace element library, based on industry standards, also simplifies shade matching.

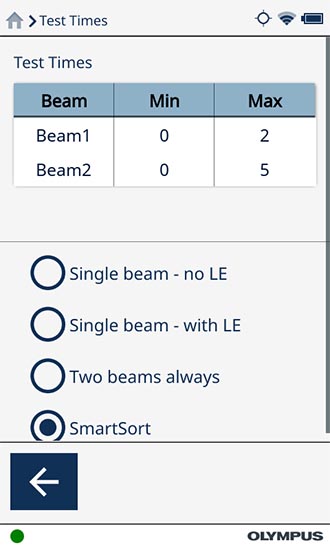

4. Make sure you work at a fast pace with SmartSort.

The SmartSort function automatically extends the analysis time for light elements such as magnesium, aluminum and silicon, if necessary, while avoiding unnecessarily long analyses for other elements.

Use SmartSort to save analysis time.

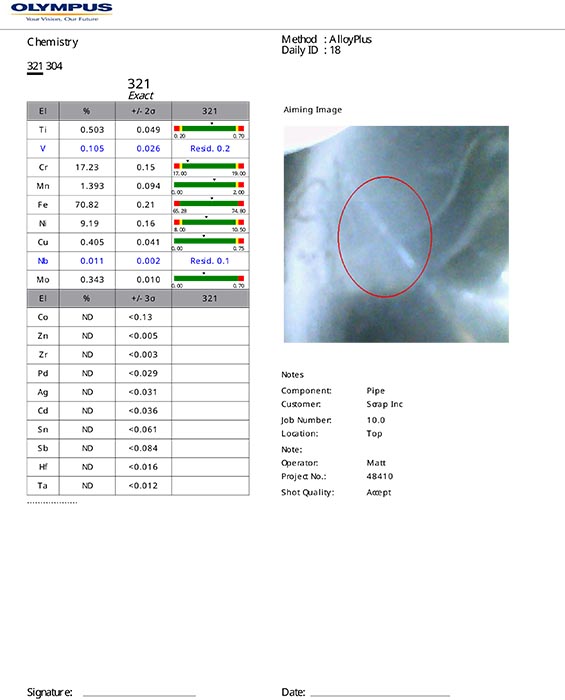

5. Take a photo of the analyzed materials.

Save and archive a photographic record of analyzed materials for enhanced visibility and reporting.

Quickly take a photo of your analyzed materials using the Vanta analyzer's camera to keep a visual record of what has been analyzed.

6. Use the collimator to isolate a small analysis area.

The optional collimator lets you isolate small elements from the background material, making it a handy tool for analyzing small components and welds.

7. Use the panoramic camera as a barcode reader.

Use the optional panoramic camera as a barcode scanner, then automatically fill in the information fields built into your analysis notes.

8. Take advantage of wireless connectivity to simplify data management.

Take advantage of optional wireless connectivity to easily incorporate XRF analysis data into your ERP system and ensure material compliance with purchasing requirements. You can also connect to theOlympus Scientific Cloud™ (OSC) to access free and paid applications designed to simplify data sharing.

9. Use integrated reporting functions to optimize data retention and traceability.

Use the built-in PDF reporting functions to combine GPS data, images and XRF analysis information into a clear summary report. You can easily add references to find related information: date, timestamp, operator notes, etc.

Integrated PDF reporting functions make it easy to store data and traceability in the field.

The importance of an end-to-end quality control and assurance process

Improved quality means better products, lower costs and greater customer satisfaction. Taking advantage of the powerful capabilities of XRF analyzers can help you meet high quality standards at every stage of your manufacturing process. To find out more about how a hand-held XRF analyzer can enhance your quality control and assurance program, visit : Vanta for quality assurance and control in the manufacturing industry.

Related content

Brochure: Vanta XRF Analyzers for Manufacturing QA/QC

Infographic: Save Time and Prevent Material Mix-Ups with Vanta Handheld XRF

Author: Damien Blondel, Environmental and Natural Resources Vertical Market Specialist

Damien joined Olympus in 2011 after living in Denmark where he was Product Manager for measurement systems for diagnostics and research into fluid mechanics. Currently, he is part of Olympus' Environment and Natural Resources (ENR) team and is based in Paris, France. His background is in mechanics (Master's Degree) and he holds a Ph.D. in physics.

Media kit

Media kit