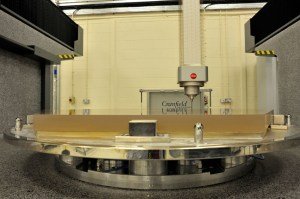

Hexagon Metrology is involved in checking the mirrors of the European Extremely Large Telescope (E-ELT), currently being built by the European Observatory. ESO (The E-ELT is a ground-based telescope with a diameter of 42 m, comprising 1,000 hexagonal mirror segments, each 1.50 m wide and just 5 cm thick. Four to five times larger than the largest optical telescopes currently in service, the E-ELT will also collect 15 times more light. The involvement ofHexagon Metrology in this program is through the University of Cranfield (UK), working on the machining of 7 telescope mirror segments. Each polished part must have a surface roughness accuracy of 1-2 nanometers emq (root mean square error) and a shape accuracy of 10 nanometers. The university has developed the BoX (Big OptiX), a measuring and smoothing system specially designed for the production of these mirrors. This system is controlled by a Leitz PMM-F 30.20.10 CMM from Hexagon Metrology. The combined action of the BoX and the Leitz PMM-F machine should enable each mirror segment to be hardened in 20 hours, a performance claimed to be 10 times faster than that offered by the competition, while surface polishing is controlled by an 8 m optical test tower. Leica Absolute Tracker AT901 from Leica Geosystems (Hexagon Metrology)The laser tracker system monitors the position of the tower's main optics during measurements. The laser tracker system monitors the position of the tower's main optics during measurements, and detects any movements due to thermal effects, which can reach several micrometers.

Learn more: www.hexagonmetrology.com

Media kit

Media kit