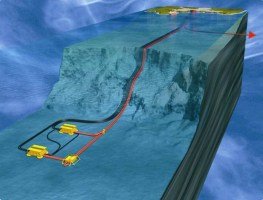

The SKF Group has announced a major contract in the oil and gas sector. 200 km off the coast of Norway lies a gas field 300 m deep. Unable to rely on natural pressure to bring the gas up, the major players in the project (including Statoil, Exxon, Total, Aker Solution, Man, SKF) have come together to develop a solution to "help" the gas to rise. A superstructure will be submerged at the bottom of the North Sea, bringing the gas to the surface.

To achieve this, SKF is at the forefront of magnetic bearing technology. These bearings could be high-speed bearings, relying on stator and rotor levitation. In this system, the shaft that drives the rotating machine is levitated and held in position by electromagnetic forces generated in radial and axial directions. These forces are generated by copper wire electromagnets controlled by sophisticated electronic components. The result: no friction and very high energy efficiency (97 %).

The aim is to have continuous operation for 5 years. To achieve this, remote monitoring is mandatory. The manufacturer offers data collection tools adapted to the required measurements, thanks to a software solution.

If this experiment on the Asgard gas field is successful, it will undoubtedly be repeated at other locations to extend the life of gas fields and preserve natural resources.

Learn more: www.skf.com

Media kit

Media kit