Gom France is organizing a workshop dedicated to industrial forging, casting and stamping applications on June 9 & 10, 2015, in partnership with Arts et Métiers ParisTech. At this event, participants will be able to see Gom technologies in operation in an industrial environment, attend demonstrations and discuss issues related to the use of the manufacturer's systems.

Process optimization

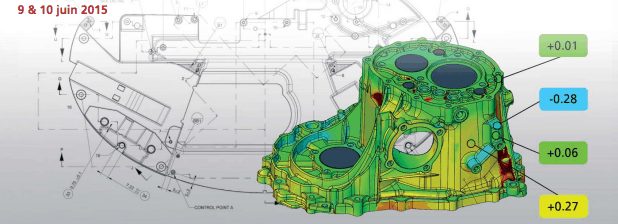

Shorter production cycles and optimized costs are forcing companies to be increasingly efficient in their development, design and optimization of production processes. Around the Vulcain platform, come and discover the contribution of non-contact 3D measurement technologies to the virtuous loop of process optimization: simulation > manufacturing > control...

Automated 3D surveying

Automation plays an increasingly important role in industrial process chains. Gom offers innovative solutions that enable companies to easily integrate non-contact metrology into automated processes. The manufacturer has extensive experience in integrated measurement solutions, setting new standards in process safety and ease of operation.

Testing for development

Optical metrology analyzes the mechanical properties and behavior of all types of materials in different test scenarios. Gom's Aramis and Pontos systems can be integrated into various environments, test benches or existing test machines. Non-contact sensors measure the full range of 3D stresses and strains in flexible or rigid materials subjected to mechanical or thermal stress. Conventional extensometers and extension gauges can be easily replaced by Gom's real-time 3D surface deformation analysis systems.

Practical information

Two sessions available: Tuesday June 9: 2 - 6 pm / Wednesday June 10: 9 am - 1 pm

Arts et Métiers ParisTech, Metz Technopôle, 4, rue Augustin Fresnel, 57078 Metz Cedex 3

Learn more: www.gom.com

Media kit

Media kit