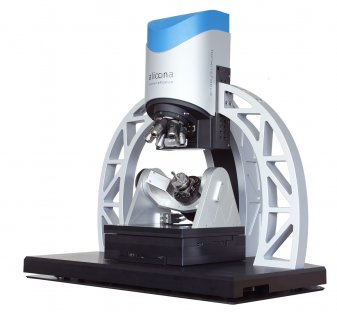

The dimensional metrology laboratory of Cetim (Centre technique des industries mécaniques) based in Senlis, France, now has an InfiniteFocusG5 AdvancedReal3D optical 3D metrology system from Bruker Alicona. With...

With this new optical 3D metrology system, Cetim has enhanced the machinery at its Senlis site, enabling it to meet both its own needs and those of manufacturers in the northern half of France. The InfiniteFocusG5, a highly versatile focal variation metrology system, can be used to carry out high-resolution 3D shape measurements on micro-geometries with very tight tolerances, as well as 2D and 3D roughness measurements in areas that are difficult for contact probes to access.

Focal variation combines the shallow depth-of-field of an optical system with its vertical scanning, to provide true-color topography information from the variation in image sharpness on the sensor. Unlike other, more traditional optical technologies, which are limited to coaxial illumination, the maximum measurable slope does not depend solely on the numerical aperture of the lens used. Focal variation can be used with a wide range of different light sources (such as ring lighting), enabling angles of over 87° to be measured on slopes. It can be used on surfaces with a wide range of different optical reflectances, a major advantage when measuring parts with complex geometries.

Detailed measurements

With 3D data files of up to 500 million points, Alicona systems are capable of delivering measurement files with a high level of detail. The high point density of the focal variation enables operators to systematically achieve very fine vertical and lateral resolutions, even on large measurement volumes, making it possible to obtain connected measurements on small radii, angles and roughnesses located in hard-to-reach areas.

The AdvanceReal3D rotation unit transforms the profilometer into a true 5-axis measuring machine. This rotation unit positions a part in a chuck, then scans it from different angles. The individual measurements thus obtained in different orientations are then automatically merged to generate a complete 3D data file. Equipped with a high-precision rotation axis and a tilt axis, both motorized and servo-driven, the AdvancedReal3D is calibrated to guarantee automated, repeatable and connected measurement of shape and roughness across the entire part geometry.

Key applications where the InfiniteFocusG5 can provide an advantage over traditional metrology methods include the measurement of micro-geometries on cutting tools and micromechanical parts, the measurement of radius and angle breakage on all types of precision or safety parts such as those found in aerospace, the characterization of non-conformities, defects or wear, and high-resolution 3D surface digitizing.

Diode-pumped femtosecond Ti:Sa lasers available in France thanks to Opton Laser International

Opton Laser International and Viulase have signed an exclusive distribution agreement for France and French-speaking Switzerland. Viulase is a young Austrian company whose founders are strong...

Media kit

Media kit