With innovation at the heart of its development, Daher is asserting its expertise in the design, manufacture and assembly of high-performance valves for the nuclear and energy sectors. The Group has developed an intelligent connected valve for predictive maintenance. This market-breaking technology represents both a strategic challenge for Daher and its customers, and a lever for operational and commercial performance.

Predictive maintenance on intelligent valves to optimize operating costs

For many years, Daher has been the benchmark in the market for high-performance valves for the nuclear and energy sectors, supporting the world's largest facilities. It was therefore natural for the Group to develop a predictive maintenance solution that can save maintenance costs in the order of 10 to 15 %.

Today, there are two types of maintenance plans chosen by operators:

- systematic periodic valve replacement according to a predefined maintenance plan, even if the valve is in perfect condition, which leads to financial losses;

- changing the valve in the event of a breakdown between two maintenance plans, which often means stopping the line and incurring additional costs. In addition to this downtime, there is the extra time required to identify the fault, order a new valve, deliver it, install it, and so on.

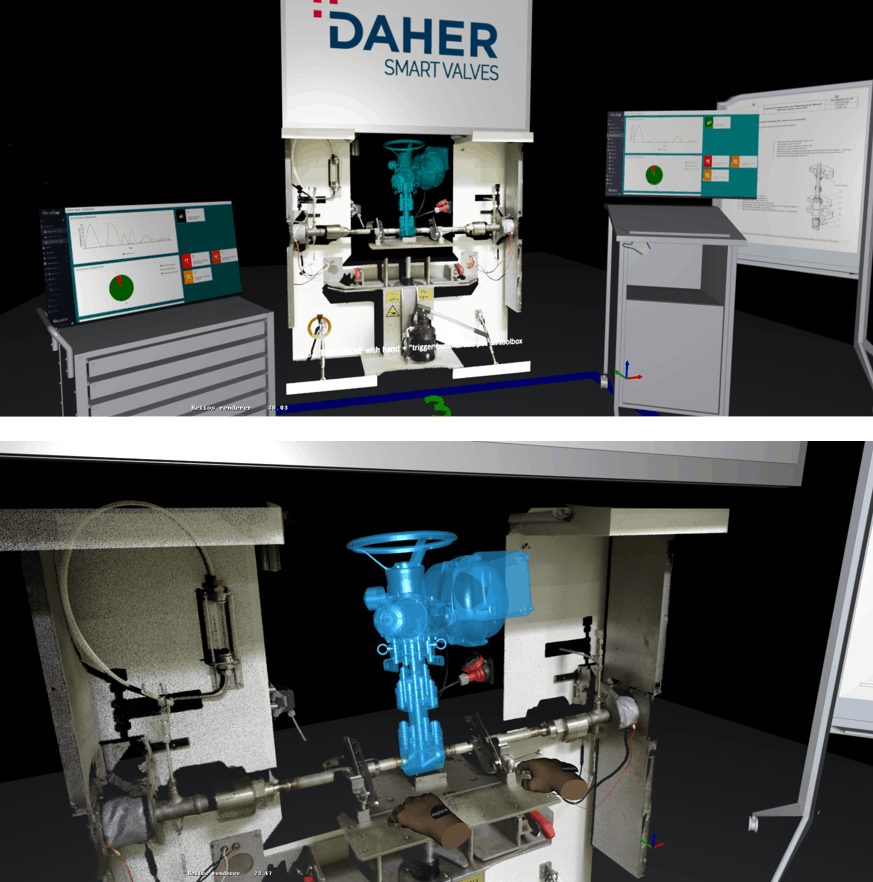

Based on this observation, Daher has carried out a development project, supported by its employees, with the aim of implementing predictive maintenance on intelligent valves. This involves equipping the valves with sensors and linking them to an IOT platform developed by Nexess, enabling them to pick up weak signals in the valve's signature (a vibration rhythm, temperature, flow rate, etc.), and thus predict possible breakdowns.

Daher acts as an expert from valve manufacture to sensor installation, right through to signal diagnosis.

"Through this project, Daher confirms its strategy in terms of innovation and digitalization, and its positioning as a designer and producer of high-performance valves. As the initial tests have proved conclusive, we aim to market this solution as early as 2019. The development of this technology is a perfect example of Daher's constructive approach to providing high-performance innovations to enhance its customers' competitiveness. This success is also due to the skills and motivation of the teams involved in this project, without whom we would not have been able to achieve all our objectives", says Hervé de Chillaz, Senior Vice-President of the Advanced Technologies business unit.

To discover Daher's unique predictive maintenance solution for intelligent valves in virtual reality, visit Daher stand 7-H69 at WNE in Paris Nord Villepinte.

Learn more: www.daher.com