VisiConsult, as a supplier of innovative X-ray solutions, has already been able to install several fully automated in-line tomography systems at a leading automotive supplier. This typical inspection is required for short-circuit rings.

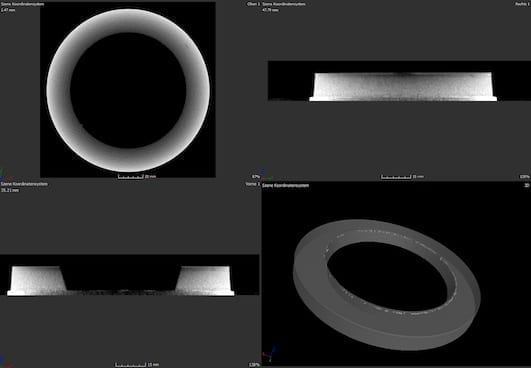

Inside the rotor, a laminated core is positioned between the shorting rings, which are connected to each other by aluminum. When casting the short-circuit rings, the greatest challenge is to ensure that the aluminum is sufficiently fluid when it reaches the end of the laminated core. If this is not the case, porosities appear and, depending on their size, are either within tolerance or lead to the elimination of the rotors. While small porosities are harmless discontinuities in the material, large porosities reduce the strength of the shorting ring. Tomography inspection with automatic defect recognition (ADR) is essential.

VisiConsult has been able to integrate numerous CT solutions into in-line production, so that its customers benefit from 100 % inspection without any loss of time. Directly after casting, the rotors can be moved for inspection as the conveyor passes through a cooling tunnel. This constant temperature ensures that inspection conditions are met. A robot then positions two rotors in the X-ray booth, which houses two X-ray tubes.

An X-ray beam can detect two short-circuit rings at its center, lying side by side. In this way, four short-circuit rings are scanned at a time. VisiConsult, a manufacturer of special X-ray machines, was able to install the complete test cell as a black box. The operator needs no X-ray or process knowledge. With loading and unloading, the in-line solution is currently available with a cycle time of 42 seconds per rotor. In addition to the time advantage, the dual X-ray source equipment also enables more accurate scanning, and ensures greater system availability thanks to this redundancy.

Depending on the customer's requirements, subsequent analysis can be carried out to VW's P202 standard or that of other vehicle manufacturers. With this system, 3D analysis is possible, which means that the part is non-destructively inspected at 100 %. If a size d ́une porosity goes beyond that of a discontinuity, it is given as a material defect and classifies the component as not OK (n.i.O.) during sorting.

"In addition to evaluation results, our systems also provide detailed information on upstream processes, such as casting. Thanks to this information, our customer's QM can be optimized and monitored in real time. The functionality is part of our industry 4.0 strategy and offers considerable value."explains Lennart Schulenburg, VisiConsult Sales Director.

In the field of electromobility, VisiConsult collaborates with Breuckmann eMobility GmbH, a subsidiary of Breuckmann GmbH & Co. KG, which offers molded rotors for electric motors.

Visit the site:

visiconsult.de